Fire Rakshak in Road and Train Tunnels

Fire Rakshak Temperature Monitoring in Warehouse

Fire Rakshak in Road and Train Tunnels

Fire Rakshak in Road and Train Tunnels

Tunnels for roads and trains are constructed from non-flammable materials however, the cars, trucks, buses, trains, and other vehicles that use these tunnels have the potential to generate major fires. Vehicles can carry hundreds of liters of highly flammable fuels or containers full of combustible goods and material. Short circuits, electrical malfunctions in control, power cables, ventilation, and air handling equipment, or something as simple as the build-up of rubbish can be ignited by a discarded cigarette can cause a massive fire in tunnels. The fire in tunnels can cause loss of human life and severe damage to the tunnel structures, which may require extensive repairs or may collapse the tunnel. The result of fire can disrupt transport links which can cause serious economic or social problems, such as increased traffic congestion, a drop in tourism, or damage to the economy.

Common causes of warehouse fires

Safety systems in modern transportation infrastructures require highly reliable, extremely fast, and reliable heat detection systems despite the high air currents typically prevailing in such tunnels. Conventional systems such as smoke and flame detectors are prone to generating false alarms as well as inaccuracy in fire location as they react to dust, fumes, water vapor, car lights, and vehicle exhaust. And because of the fact that these detectors monitor discrete points only, they have limited flexibility and have lots of blind spots. Conventional fixed temperature linear heat detectors have been used in tunnels, but they are often limited by their range and inability to predict a fire before it actually happens. The alarm parameters for these systems are already predefined during manufacturing. Technica Fiber Tech’s Fire Rakshak is based on fiber-optic Linear Heat Detection technology with the ability to both monitor temperature and set pre-alarm and alarm criteria programmatically based on the temperatures and rates-of-rises is the best heat detection system for tunnels.

Fire Rakshak and Its Working Principle

Technica Fiber Tech’s Fire Rakshak is based on the temperature-dependent Raman scattering of laser light within optical fibers. It uses optical fiber as a continuous sensor that is very light and easy to install. Thousands of temperature sensors along with the sensor cable measure in real-time, pinpointing any heat or fire with absolute accuracy. Fire Rakshak is an extremely robust and reliable system capable of continuous measurement of temperature and precise localization of the thermal event along our fiber-optic cable with a minimum sampling resolution of 1 m or less. The major advantage of Fire Rakshak is the flexibility to adjust and set the alarm parameters based on set temperature thresholds such as rate of rising, maximum temperature, and differential zonal temperature.

The Fire Rakshak sends a laser beam through the optical fiber cable. The glass fiber reflects this light and scatters it back – split into “Stokes” and ”Anti-Stokes” signals (Raman Effect). While Stokes signals have nearly the same signal amplitude at all temperatures, the amplitude of Anti-Stokes signals changes proportionally to the temperature. By comparing both Stokes and Anti-Stokes the Fore Rakshak reliably calculates the current temperature within seconds identifying the exact location of fires for effective countermeasures. Through optimization of temporal and local resolution, even slight temperature changes – such as an increase of a few degrees Celsius per minute – can be reliably and exactly displayed.

The Fire Rakshak can be integrated with customer communication networks, in order to provide automatic activation of supervisor and protective systems, based on specific information on the different zones under monitoring. In each zone, several typologies and specific threshold values can be defined in order to quickly predict fire without false alarms, e.g. maximum temperature values, and spatial and temporal temperature gradients can be defined in each zone to provide key information on the affected area.

Tunnels for roads and trains are constructed from non-flammable materials however, the cars, trucks, buses, trains, and other vehicles that use these tunnels have the potential to generate major fires. Vehicles can carry hundreds of liters of highly flammable fuels or containers full of combustible goods and material. Short circuits, electrical malfunctions in control, power cables, ventilation, and air handling equipment, or something as simple as the build-up of rubbish can be ignited by a discarded cigarette can cause a massive fire in tunnels. The fire in tunnels can cause loss of human life and severe damage to the tunnel structures, which may require extensive repairs or may collapse the tunnel. The result of fire can disrupt transport links which can cause serious economic or social problems, such as increased traffic congestion, a drop in tourism, or damage to the economy.

Common causes of warehouse fires

Safety systems in modern transportation infrastructures require highly reliable, extremely fast, and reliable heat detection systems despite the high air currents typically prevailing in such tunnels. Conventional systems such as smoke and flame detectors are prone to generating false alarms as well as inaccuracy in fire location as they react to dust, fumes, water vapor, car lights, and vehicle exhaust. And because of the fact that these detectors monitor discrete points only, they have limited flexibility and have lots of blind spots. Conventional fixed temperature linear heat detectors have been used in tunnels, but they are often limited by their range and inability to predict a fire before it actually happens. The alarm parameters for these systems are already predefined during manufacturing. Technica Fiber Tech’s Fire Rakshak is based on fiber-optic Linear Heat Detection technology with the ability to both monitor temperature and set pre-alarm and alarm criteria programmatically based on the temperatures and rates-of-rises is the best heat detection system for tunnels.

Fire Rakshak and Its Working Principle

Technica Fiber Tech’s Fire Rakshak is based on the temperature-dependent Raman scattering of laser light within optical fibers. It uses optical fiber as a continuous sensor that is very light and easy to install. Thousands of temperature sensors along with the sensor cable measure in real-time, pinpointing any heat or fire with absolute accuracy. Fire Rakshak is an extremely robust and reliable system capable of continuous measurement of temperature and precise localization of the thermal event along our fiber-optic cable with a minimum sampling resolution of 1 m or less. The major advantage of Fire Rakshak is the flexibility to adjust and set the alarm parameters based on set temperature thresholds such as rate of rising, maximum temperature, and differential zonal temperature.

The Fire Rakshak sends a laser beam through the optical fiber cable. The glass fiber reflects this light and scatters it back – split into “Stokes” and ”Anti-Stokes” signals (Raman Effect). While Stokes signals have nearly the same signal amplitude at all temperatures, the amplitude of Anti-Stokes signals changes proportionally to the temperature. By comparing both Stokes and Anti-Stokes the Fore Rakshak reliably calculates the current temperature within seconds identifying the exact location of fires for effective countermeasures. Through optimization of temporal and local resolution, even slight temperature changes – such as an increase of a few degrees Celsius per minute – can be reliably and exactly displayed.

The Fire Rakshak can be integrated with customer communication networks, in order to provide automatic activation of supervisor and protective systems, based on specific information on the different zones under monitoring. In each zone, several typologies and specific threshold values can be defined in order to quickly predict fire without false alarms, e.g. maximum temperature values, and spatial and temporal temperature gradients can be defined in each zone to provide key information on the affected area.

Benefits of Fire Rakshak:

Benefits of Fire Rakshak:

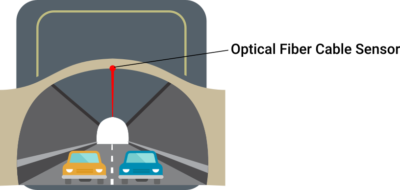

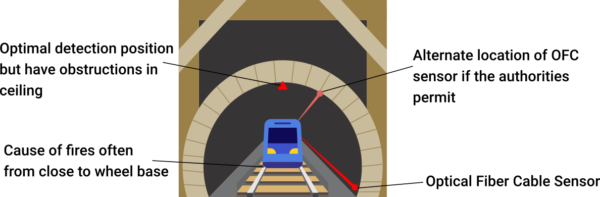

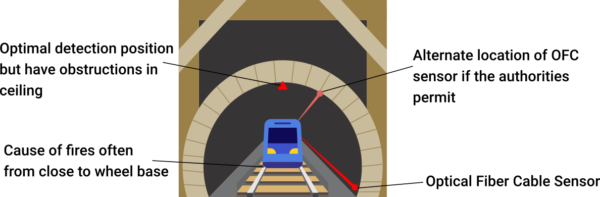

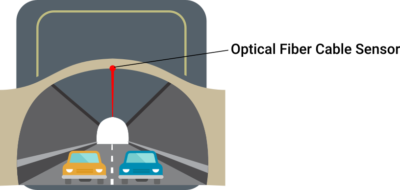

Cable Positioning

The layout and makeup of the tunnel will determine how our optical fiber cable sensor can be installed and configured. Depending on the tunnel size and dimensions, one or two cables may be required. System design should consider:

- Optical Fiber cable to be installed above the center of each lane or rail track.

- Optical Fiber cable to be installed in service tunnels.

- Optical Fiber cable to be installed along with cable trays.

Wrapping Up!

Technica Fiber Tech can be your long-term partner. We understand our customer’s challenges and deliver the best solution to them. Our Fire Rakshak will meet your heat detection and monitoring demands and protect your valuable assets. If you want a live demo or know more about our offering and capabilities contact us at [email protected].

Cable Positioning

The layout and makeup of the tunnel will determine how our optical fiber cable sensor can be installed and configured. Depending on the tunnel size and dimensions, one or two cables may be required. System design should consider:

- Optical Fiber cable to be installed above the center of each lane or rail track.

- Optical Fiber cable to be installed in service tunnels.

- Optical Fiber cable to be installed along with cable trays.

Wrapping Up!

Technica Fiber Tech can be your long-term partner. We understand our customer’s challenges and deliver the best solution to them. Our Fire Rakshak will meet your heat detection and monitoring demands and protect your valuable assets. If you want a live demo or know more about our offering and capabilities contact us at [email protected].